Description

Cummins 3678611 Plug: A Small Part with a Critical Role

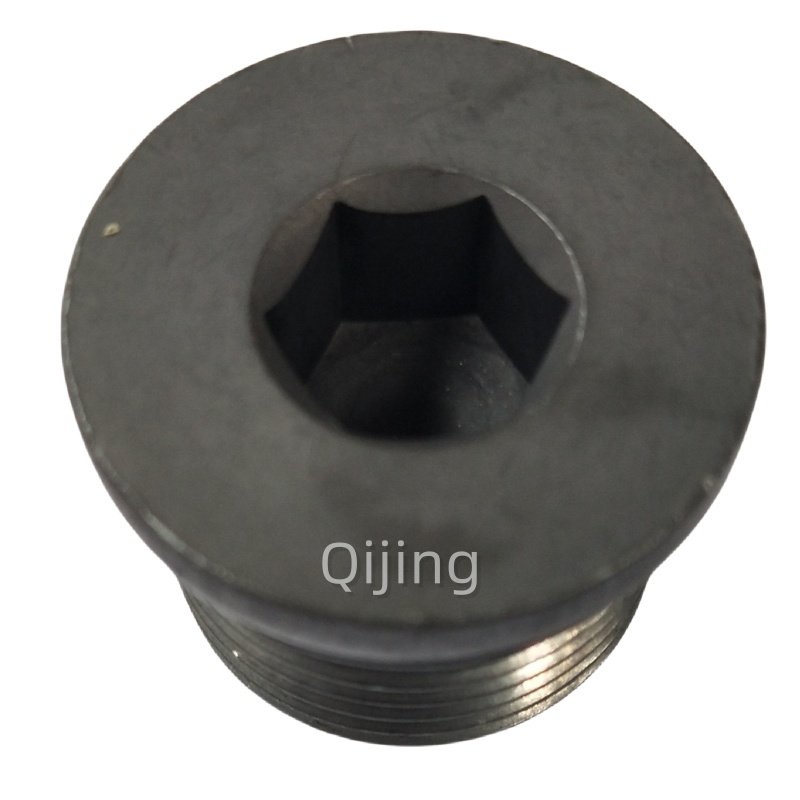

The Cummins 3678611 plug is a precision-engineered component used to seal designated ports in diesel engine systems. Although it may appear simple, its function is essential for maintaining internal pressure and preventing fluid leakage. In modern diesel engines, even minor sealing failures can result in oil loss, contamination, or reduced system efficiency.

Therefore, selecting the correct engine plug is a fundamental aspect of reliable engine maintenance.

Why Engine Plugs Matter in Diesel Systems

Diesel engines contain multiple threaded ports used for oil passages, coolant channels, and inspection points. Once these ports are no longer required for flow or access, they must be sealed properly. Otherwise, leaks may develop under pressure.

As a result, a high-quality diesel engine plug like the Cummins 3678611 plug ensures that unused ports remain completely sealed. Moreover, proper sealing supports pressure balance and protects nearby components from contamination.

Design and Material Advantages of Cummins 3678611 Plug

The Cummins 3678611 plug is manufactured from durable metal materials designed to withstand high temperatures, vibration, and pressure fluctuations. In addition, its precise threading ensures a tight fit with engine housings.

Key design benefits include:

-

Accurate thread dimensions for secure installation

-

Strong resistance to thermal expansion and contraction

-

Excellent durability under continuous engine vibration

-

Long service life in heavy-duty operating conditions

Because of these features, this plug is widely used in commercial vehicles, industrial engines, and construction machinery powered by Cummins diesel engines.

Installation Guidelines and Best Practices

Proper installation is essential for optimal sealing performance. First, the threaded port should be cleaned to remove debris or old sealing material. Next, the plug should be installed evenly and tightened to the recommended torque specification.

Additionally, over-tightening should be avoided. Excessive force may damage threads or deform the plug, which can reduce sealing effectiveness over time. Therefore, following Cummins installation guidelines helps ensure long-term reliability.

Common Applications in Diesel Engines

The Cummins 3678611 plug is typically used in:

-

Engine oil passage sealing

-

Cylinder block or head ports

-

Auxiliary fluid channel closures

-

Maintenance and inspection port sealing

Because these locations often operate under pressure, using the correct plug significantly reduces the risk of leakage and unexpected downtime.

Maintenance and Replacement Considerations

Although engine plugs are durable, they should still be inspected during major engine service intervals. If signs of corrosion, thread wear, or leakage appear, replacement is recommended.

Moreover, using the exact part number ensures compatibility. Generic substitutes may not provide the same sealing precision, which can lead to long-term reliability issues.

Why Choose Genuine Cummins Engine Plugs

Genuine Cummins parts are designed to match original engine specifications precisely. Consequently, they offer better sealing consistency and longer service life than non-standard alternatives.

Furthermore, OEM-quality plugs help maintain engine integrity and reduce the risk of secondary damage caused by leaks. For this reason, professional technicians and fleet operators consistently choose original Cummins components.

Conclusion

In summary, the Cummins 3678611 plug plays a vital role in maintaining diesel engine sealing and pressure stability. While small in size, its contribution to engine reliability is significant. By selecting the correct plug and installing it properly, operators can prevent leaks, protect engine systems, and extend service life.

🔗 More Information

For official specifications and technical details, visit the Cummins website: cumminsdongfeng.com